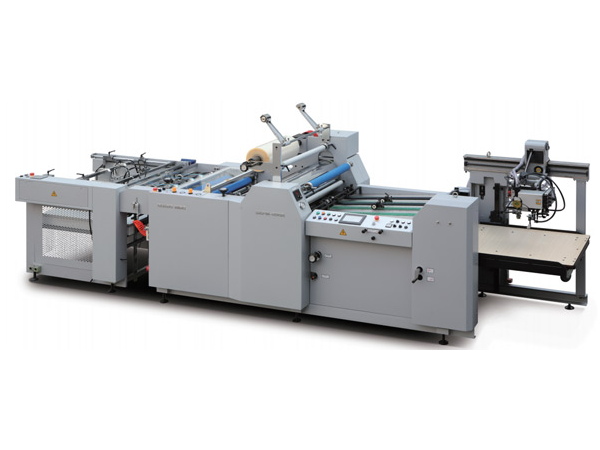

YDFM – 720/920/1200 Manual Hydraulic Single Sided Paper Laminating Machines

371.800,00 ден – 543.400,00 ден +18% vat

Features:

– YDFM series of hydraulic laminating machines are compact and economical laminators. With its design, it brings: manual paper placement, a system of manual hydraulic pressure on the front rollers, automatic lamination and automatic winding of the finished plastic. Paper after lamination should be cut and torn manually. The compact structure makes this laminator occupy very little space. Manual hydraulic pressure on the front rollers provides high pressure which in turn guarantees excellent lamination quality. The excellent lamination performance completely solves the flake-air bubble problem that occurs in traditional lamination with mechanical pressure on the front rollers, ensures high lamination production and reduces lamination costs. It uses adhesive film for lamination - so-called thermal film or BOPP. This type of laminator is an excellent choice for small and medium-sized enterprises - printing houses and digital studios.

Configuration:

– One-piece construction makes the machine very stable in operation and with a long service life

– Manually feeding the paper into the machine via conveyor belts

– The construction of the board for putting paper in the machine allows for easy and precise regulation of putting the paper in the machine

– The highly precise chrome-plated front heated roller is equipped with a built-in tubular heating system of the roller, i.e. tubular heaters are placed in its cavity. It ensures perfect evenness of temperature at every point along the length of the roller and also perfectly fine temperature regulation of the chrome roller

– Manual hydraulic pressure on the front rollers that provides high and constant pressure, which guarantees perfect lamination quality

– Manual mechanical pressure on the rear rollers

– On the right side of the machine at the front, mounted on a special bar, there is a metal handle with a circular blade for cutting the foil in width while it is still in the roll.

– On the left side of the machine in front, mounted on the same bar, there is a metal handle with a circular serrated blade – a perforator that perforates the foil and enables easy automatic tearing-cutting of the laminate

– After lamination, the paper can be wound on an additional shaft, which is regulated depending on the width of the paper, and then unwound and torn off-cut manually or directly to tear off the laminate after exiting the back of the machine without winding it first

Technical characteristics:

| model | 720 | 920 | 1200 |

| max. paper width | 700 mm | 900 mm | 1200 mm |

| lamination speed | 0-30 m/min | 0-30 m/min | 0-30 m/min |

| mac. tempera. of lamination | 130 S | 130 S | 130 S |

| mac. paper thickness | 80-500 g/m2 | 80-500 g/m2 | 80-500 g/m2 |

| moknost na motorot | 1.1 KW | 1.5 KW | 2.2 KW |

| wetness | 8 KW | 8 KW | 10 KW |

| machine weight. | 470 kg | 520 kg | 600 kg |

| dimensions of machines. | 1900x1300x1600 mm | 1900x1500x1600 mm | 1900x1700x1600 mm |

| YDFM | 720, 920, 1200 |

|---|