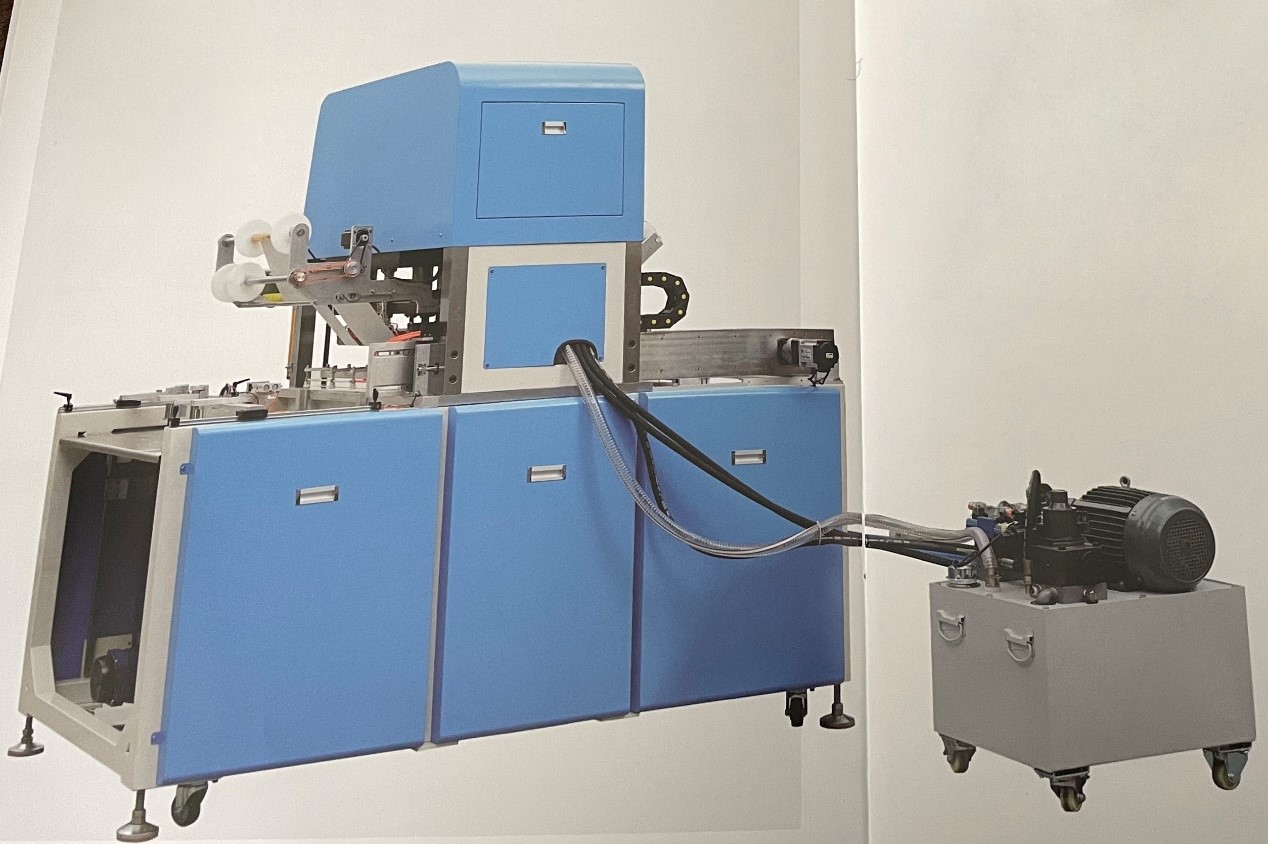

Characteristics

- High pressure: It uses three-cylinder hydraulic pressure, double auxiliary cylinders to control the lifting and lowering of the platform, and the main cylinder is responsible for the pressure and pressure maintenance, under the condition of higher pressure and higher stability, Max. Press pressure up to 10 tons.

- High precision: Adopt side gauge servo motor control to help the the positioning na the products. Stamping accuracy can reach ± 0.10 mm

- It includes three working modes, according to customer needs, choose the mode suitable for your products. It is suitable for work with foil for hot stampinggoing and foil work with foil embossingth.

- High efficiency: Using high-performance motion controller, centralized control, more accurate jumping. Adopt two rolls of stamp film, it can work in two colors or stamp in two positions at the same time, greatly increase the working efficiency.

- Paper loading system: loading is by servo motor control, it's a lot more stable is and with high precision.

- PLC system: The electrical control system is Japanese MITSUBISHI PLC computer automatic control for complete detection and control, stable and accuracy. SCHNEIDER and OMRON Electrical component.

- Safety system: The machine is equipped with various safety protection units. Any error will give a visual and audible alarm and the machine will automatically shut down to protect personal safety and device safety.

| model | 800 |

| max paper format | 800 x 550 mm |

| min paper format | 100 x 100 mm |

| max print format | 550 x 450 mm |

| min print format | 10 x 10 mm |

| paper thickness | 80 – 1,500 gsm |

| print speed | 1200 – 1500 times/hour |

| max pressure | 10 ton |

| temperature | 0 – 300 C |

| paper input/output | 800 mm / 500 mm |

| power | 3 x 380 V, 50 Hz, 9.25 KW |

| weight | 1,600 kg |

| dimensions | 2100*1400*2100mm |

| PRICE IN USD + 18%vat | request a quote |

Reviews

There are no reviews yet.